ENSA Paris Malaquais, France

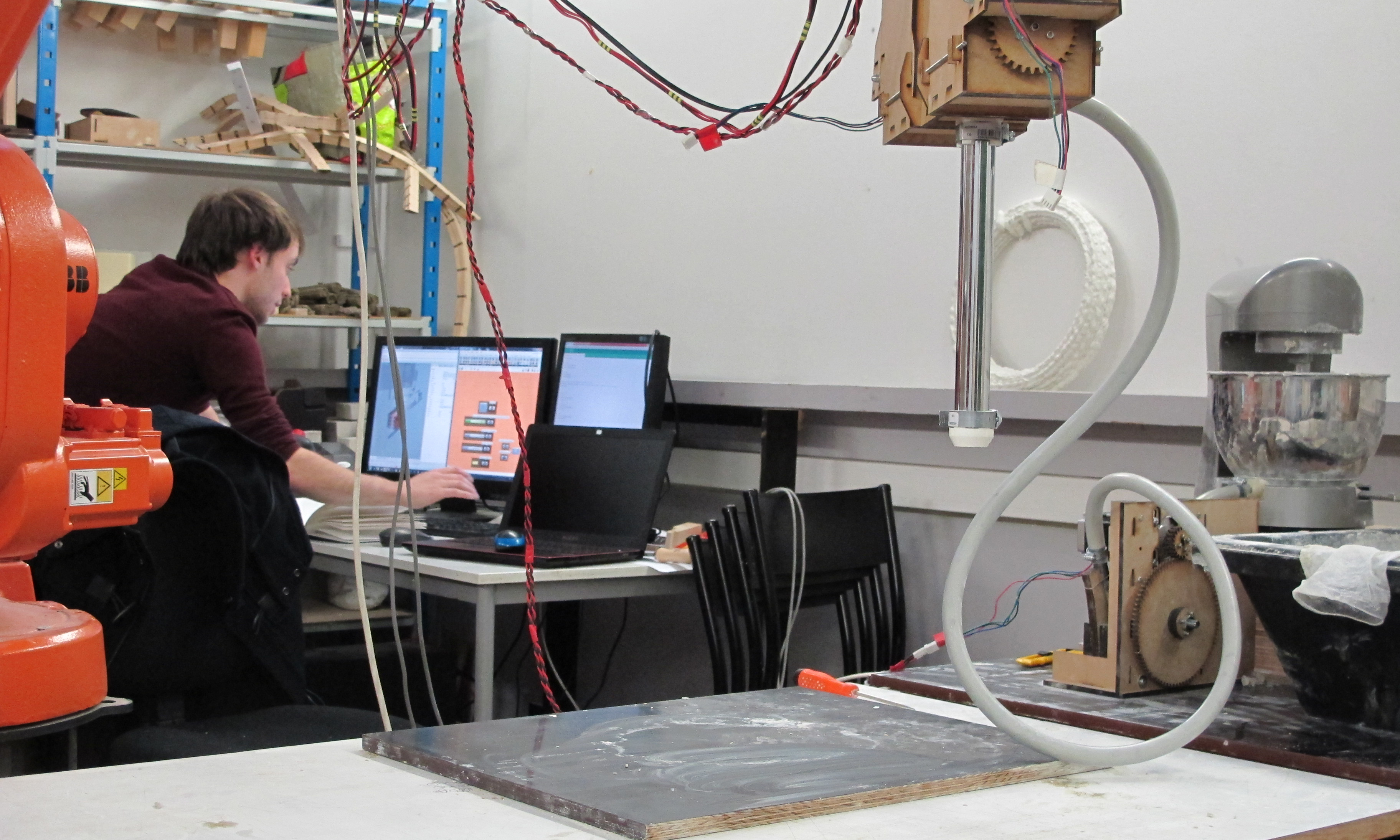

My master thesis also focused on large scale additive manufacturing process of cementitious material. This was a scientific work that contains a series of research and experiment about that focused on cementitious material adapted to additive manufacturing process. The following thematics were approached: cementitious material formulation, rheological characterization, mechanical evolution across time of young age cementitious material, mechanical performance characterization.

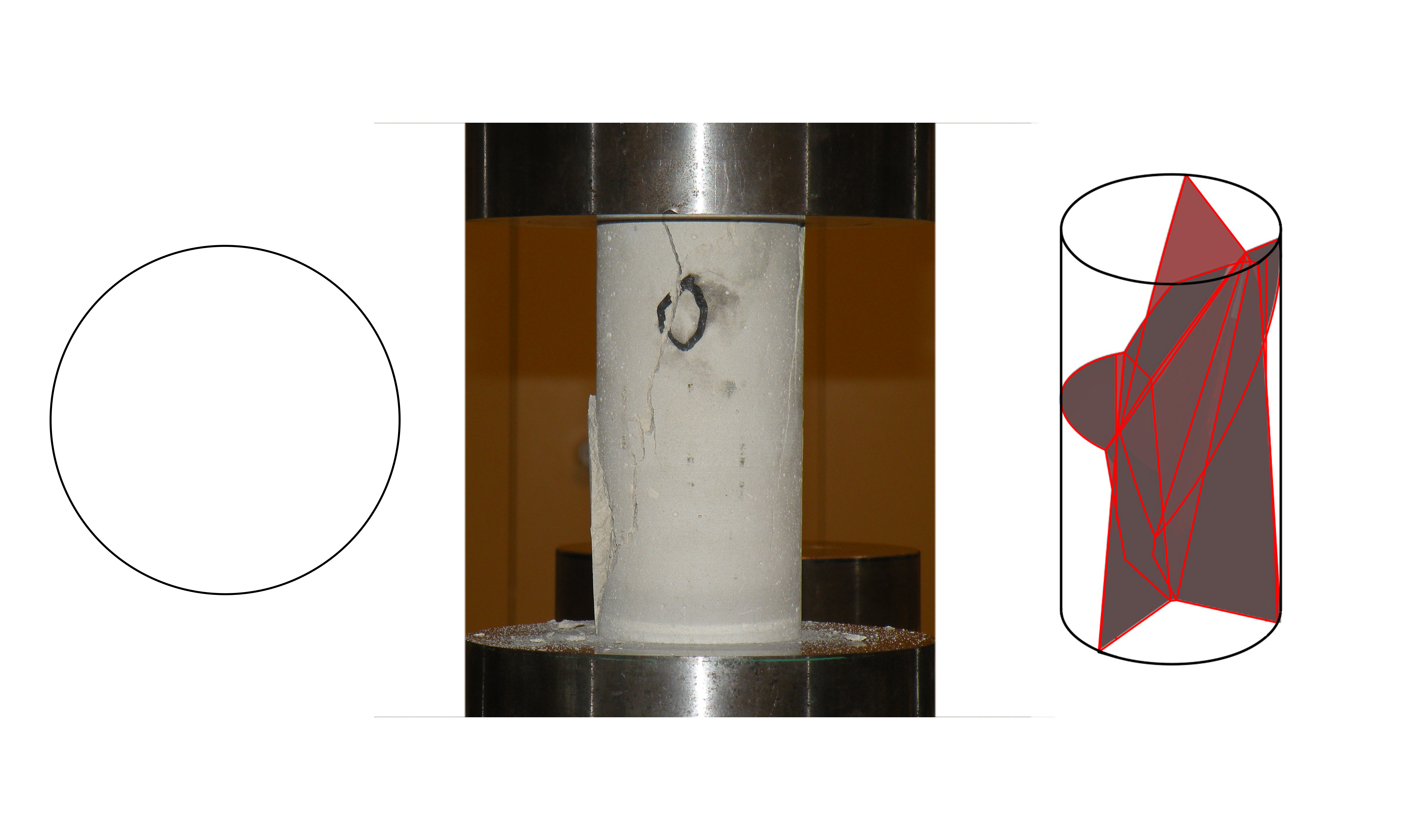

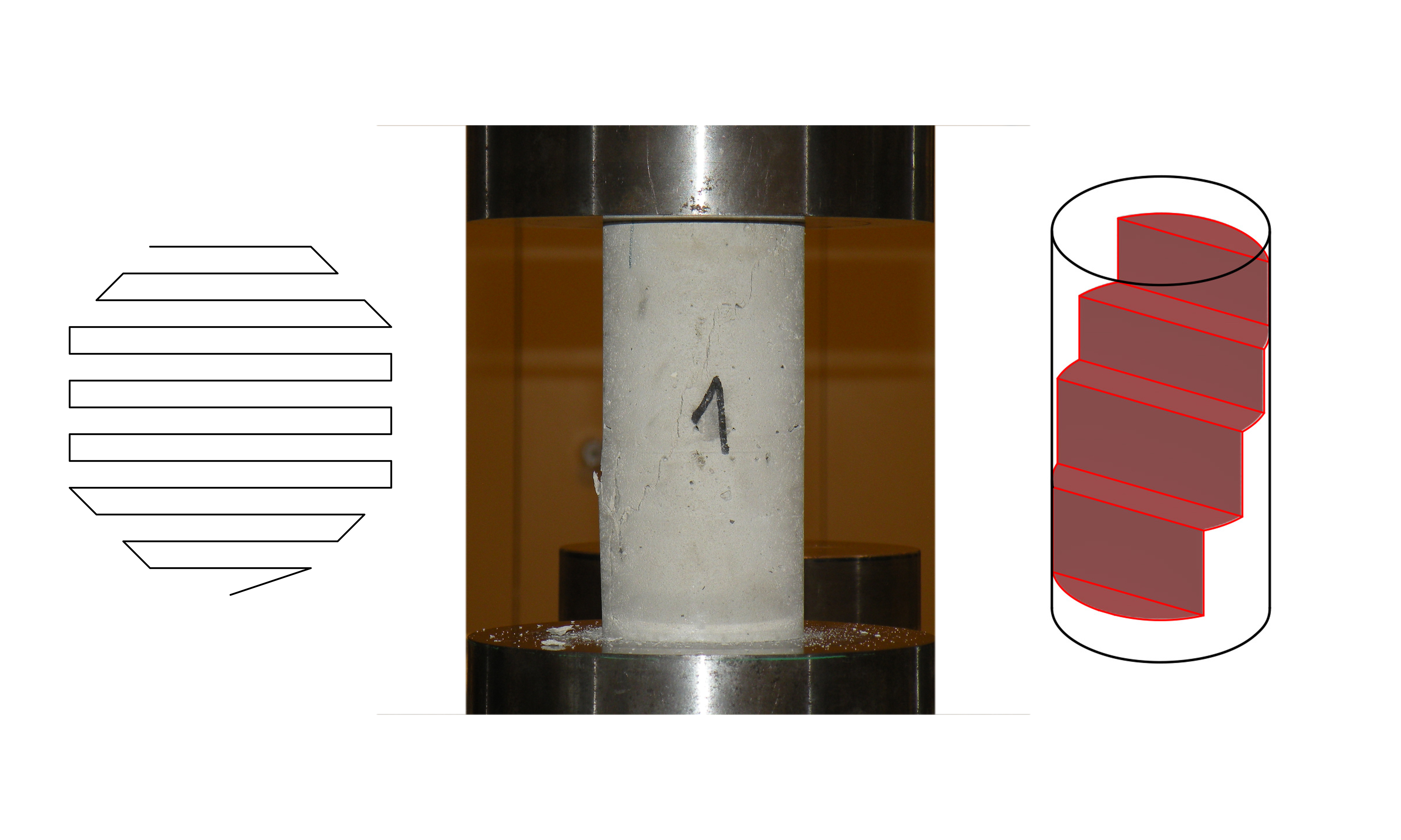

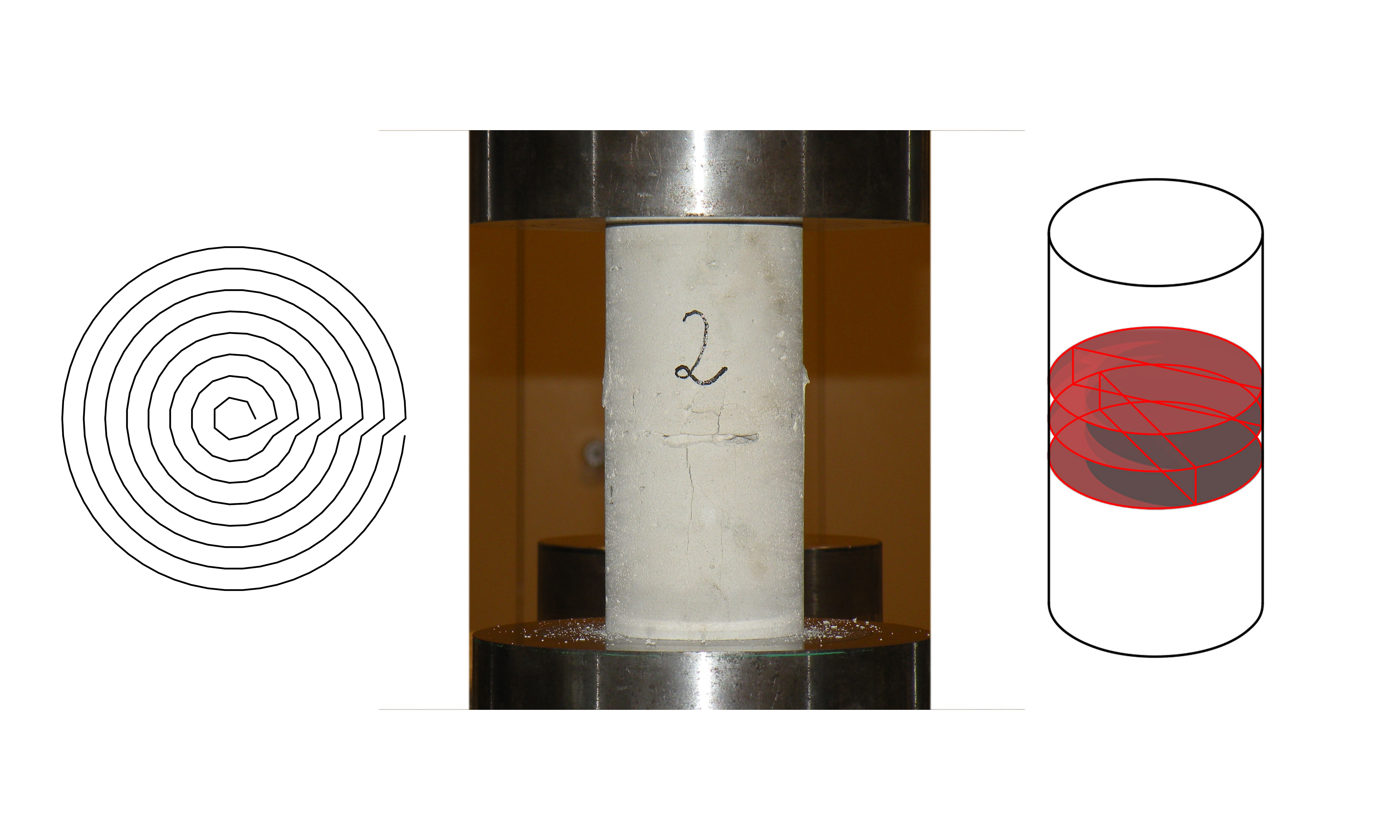

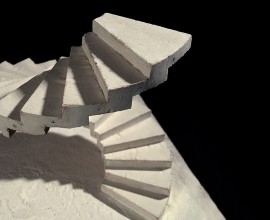

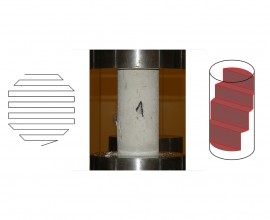

Thus, compression mechanical tests were realized on cylindrical specimen to characterize two things: the different about mechanical performance between poured and printed mortar and the impact of the toolpath, whether the laces orienta-tion, on the mechanical performances and the fracture method of printed objects. The experiment consisted of realized three cylindrical specimens made to be tested in compression. One poured mortar specimen and two printed mortar specimens, each of them with a different toolpath. One was realized with an orthogonal toolpath and the other with a concentric one.

A part of this work was published in the article Additive manufacturing and multi-objective optimization of graded polystyrene aggregate concrete structures, Design Modeling Symposium, springer 2015.