Romain DUBALLET (ENPC / ENSAPM, Paris, France)

Clément GOSSELIN (ENSAPM, Paris France)

Philippe ROUX (ENSAM / ENSAPM, Paris France

We present in this paper a work on multi-material additive manufacturing, linking a GA-based multi-objective optimization form-finding algorithm to a robotic fabrication system for prototyping cement based materials. The genetic algorithm is written entirely in Mathematica® and works on multi-material voxel spaces. It produces optimized material distributions, evaluated both in terms of mechanical performances and thermal insulation abilities. The genetic functions are based on 3D-Voronoi diagram representations and the evolution includes an adaptative penalization strategy (Hamda et al., 2002) for taking constraints into account (maximum deflections, material resistances, geometric or manufacturing needs). Both thermal and mechanical evaluations, to be combined in a Min-Max method based multi-objective fitness, are conducted thanks to Mathematica® 10 Finite-Element Method library for solving partial differential equations. We have implemented a function to compute volumetric stress distribution in a multi-material voxel space together with structure deformation. The same method is used to evaluate thermal performances: under imposed surface temperatures, the thermal distribution is calculated and the global conductive flow is extracted. The form-finding algorithm is scale-independent, and can work with any list of materials, as long as they can be characterized in terms of Young modulus, Poisson coefficient, and thermal conductivity.

We address the prototyping problem by working with concrete mixed with polystyrene beads. Therefore the aim is the making of functionally graded material structures, each part (voxel) of them varying from purely structural concrete to almost purely insulating polystyrene. The additive manufacturing system we designed allow us to print different material performance at a large scale (the deposit lace has a diameter of 2cm).

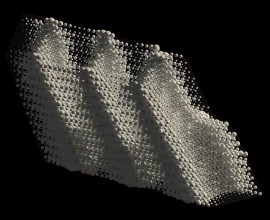

We have been able to print prototypes. They were made to calibrate the fabrication process in terms of concrete formulation (Roussel, N., Stefani, C., Leroy, R., 2005) and deposition reliability. The two pictures shown below show a piece of wall with a wavy structural material in the middle and an insulating material in each side of it.

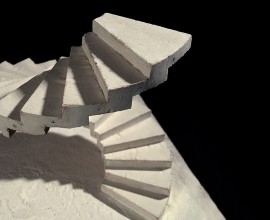

We have also addressed some less straightforward constructive scenarios like printing geometries that include empty spaces to be filled either with flexion-resistant material like UHPFC (as shown in the pictures below), tension cables, or specific architectural parts of the element (pipes, electric wire, etc.).

Now that we have a fully operating form finding and manufacturing process for the making of lightweight multi-purpose concrete and polystyrene structures, we are about to link them together. Writing our own algorithm gives a great versatility to our approach, for we can easily simulate any architectural performance or feasibility constraint that our solutions are to respect. Our algorithm also being scale-independent, it is also possible to use it to address multi-scale problems, playing with the search space, the objectives, and the constraints as inputs. Furthermore, because the construction process is completely automated and computer controlled, we can easily adjust each step to ensure our simulation fits with the actual making. Prototyping allows to conduct mechanical and thermal tests, to provide the initial form finding with quantified feedback, and thus to tighten the whole performance oriented (Hensel M., 2013) architectural approach.

REFERENCES

_Chapdelaine, F., 2007, Étude fondamentale et pratique sur le pompage du béton , Université LAVAL de Montréal.

_Hamda, H., Jouve, F., Lutton, E., Schoenauer, M., Sebag, M., 2002, Compact Unstructured Representations for Evolutionary Design, Applied Intelligence, Volume 16, Issue 2, pp39-155.

_Hensel M., 2013, performance oriented architecture rethinking architectural design and the built environment, AD primers.

_Hiller, J.D., Lipson, H., 2009, Multi material topological optimization of structures and mechanisms, GECCO ’09 Proceedings of the 11th Annual conference on Genetic and evolutionary computation, pp1521-1528.

_Kwon, Hongkyu, August 2002, Experimentation and analysi of contour crafting (CC) process using uncured ceramic materials. A Dissertation Presented to the FACULTY OF THE GRADUATE SCHOOL UNIVERSITY OF SOUTHERN CALIFORNIA In Partial Fulfillment of the Requirements for the Degree DOCTOR OF PHILOSOPHY (INDUSTRIAL AND SYSTEMS ENGINEERING).

_Roussel, N., Stefani, C., Leroy, R., 2005, From mini-cone test to Abram cone test: measurement of cement-based material yield stress using slump tests. Cement and Concrete Research.